Sustainable Printing IMPRIMA™

IMPRIMA™, Sustainable waterless printing plate, realizes simple and smart printing that is different from conventional offset printing requires craftsmanship. In addition to paper-based materials, it is used in daily and industrial products such as labels, security cards, and decorative molding film to maintain stable quality. Sold to more than 50 countries around the world, making the manufacturing process skillless and improving productivity.

It is a printing plate with high environmental performance, such as zero dampening water chemicals and waste liquid, and significantly reduced VOC emissions during printing.

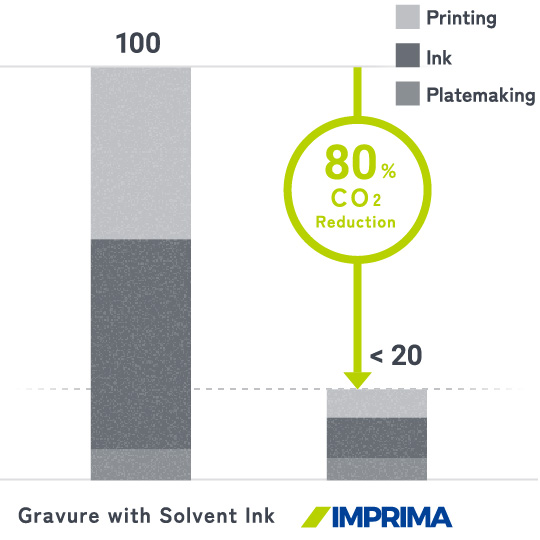

Environmental superiority (1): Reduced CO2 emissions

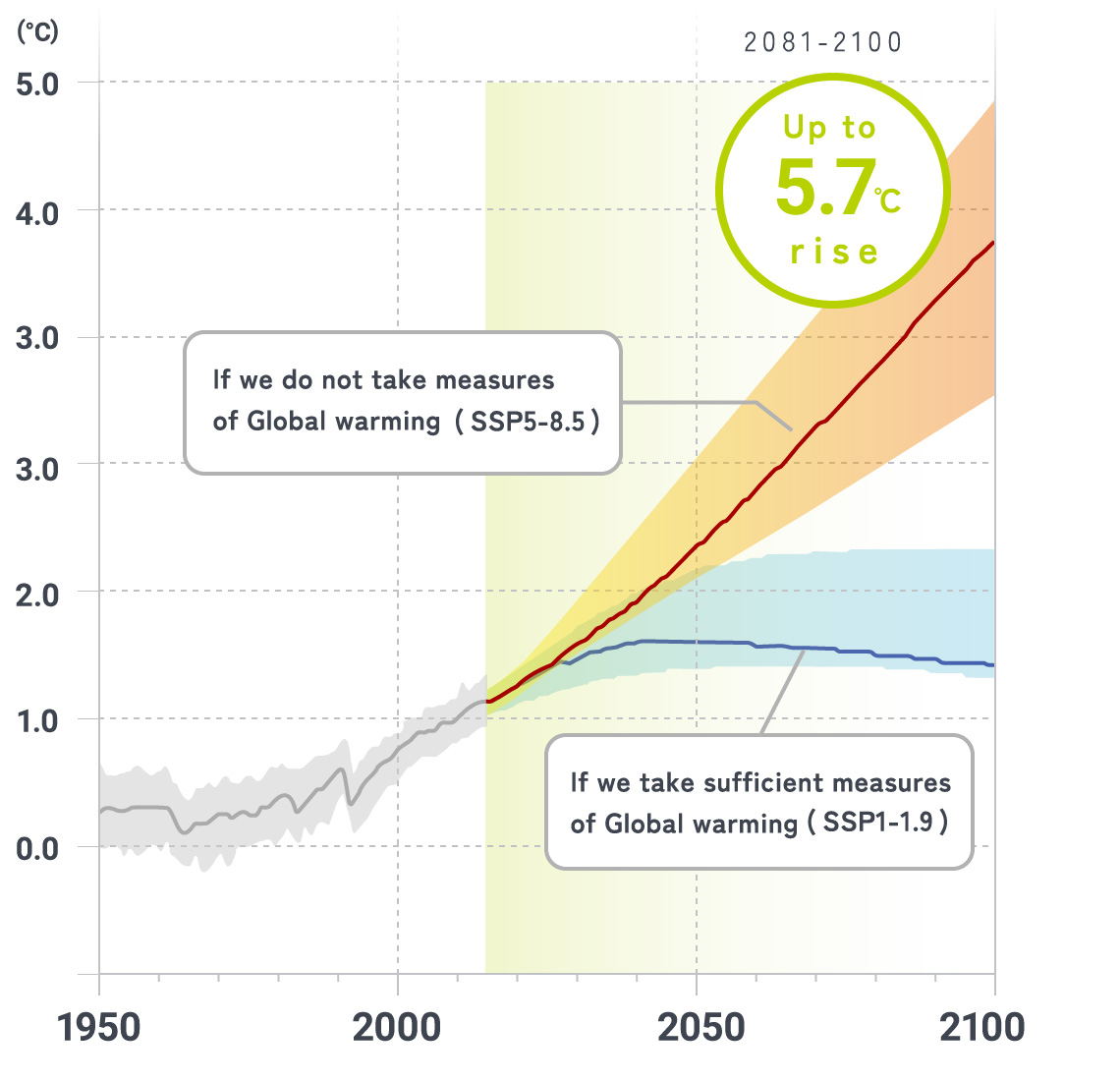

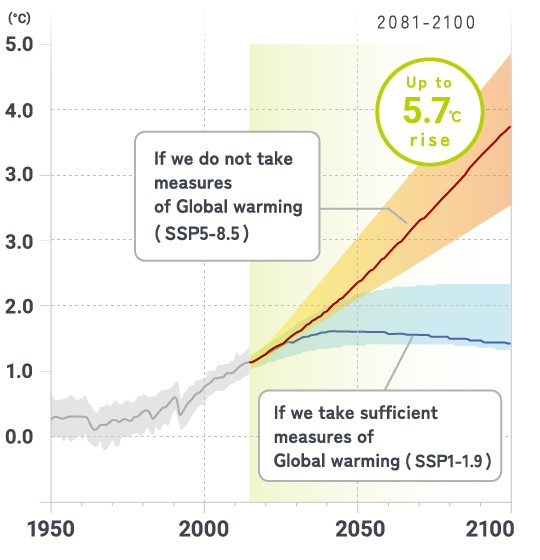

Greenhouse gases emitted during our daily lives and economic activities, such as CO2, are the main causes of global warming, which has become a social issue in recent years. If greenhouse gases continue to increase on their current trajectory and the average temperature rises, the global environment will be deteriorated and there will be increases in risks of abnormal weather, floods, rising sea levels, forest fires, and extinctions of plants and animals.

Not only will this cause tremendous damage to our lives and health, but it will have negative impacts on our children. It is very important that every single person is conscious of saving energy in daily lives and reducing CO2 emissions. IMPRIMA™ waterless offset printing system can significantly reduce CO2 emissions in comparison to solvent gravure printing and solvent flexographic printing, contributing to the carbon neutrality.

Climate change observations and predictions from 1950 to 2100

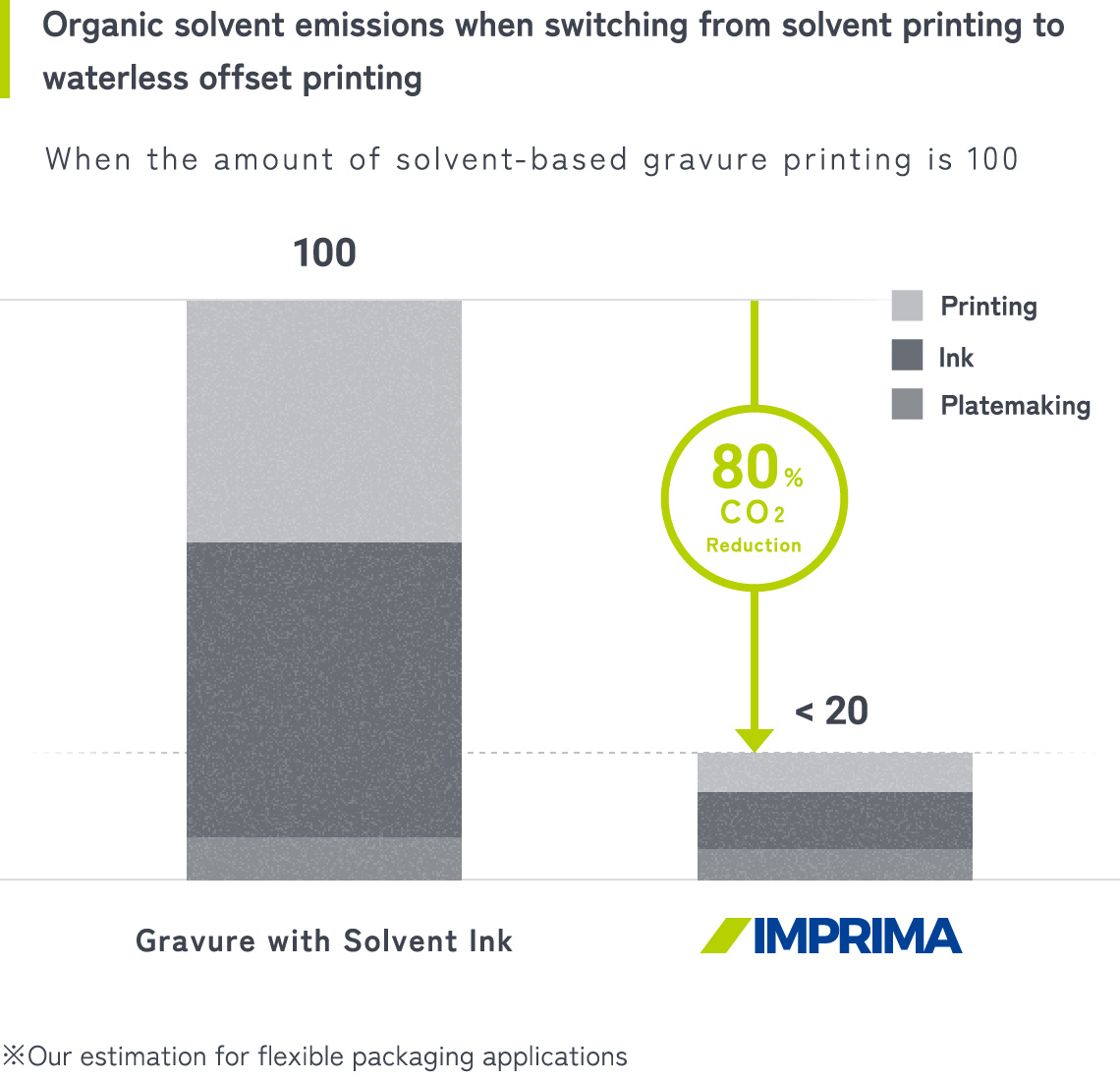

CO2 emissions by printing method

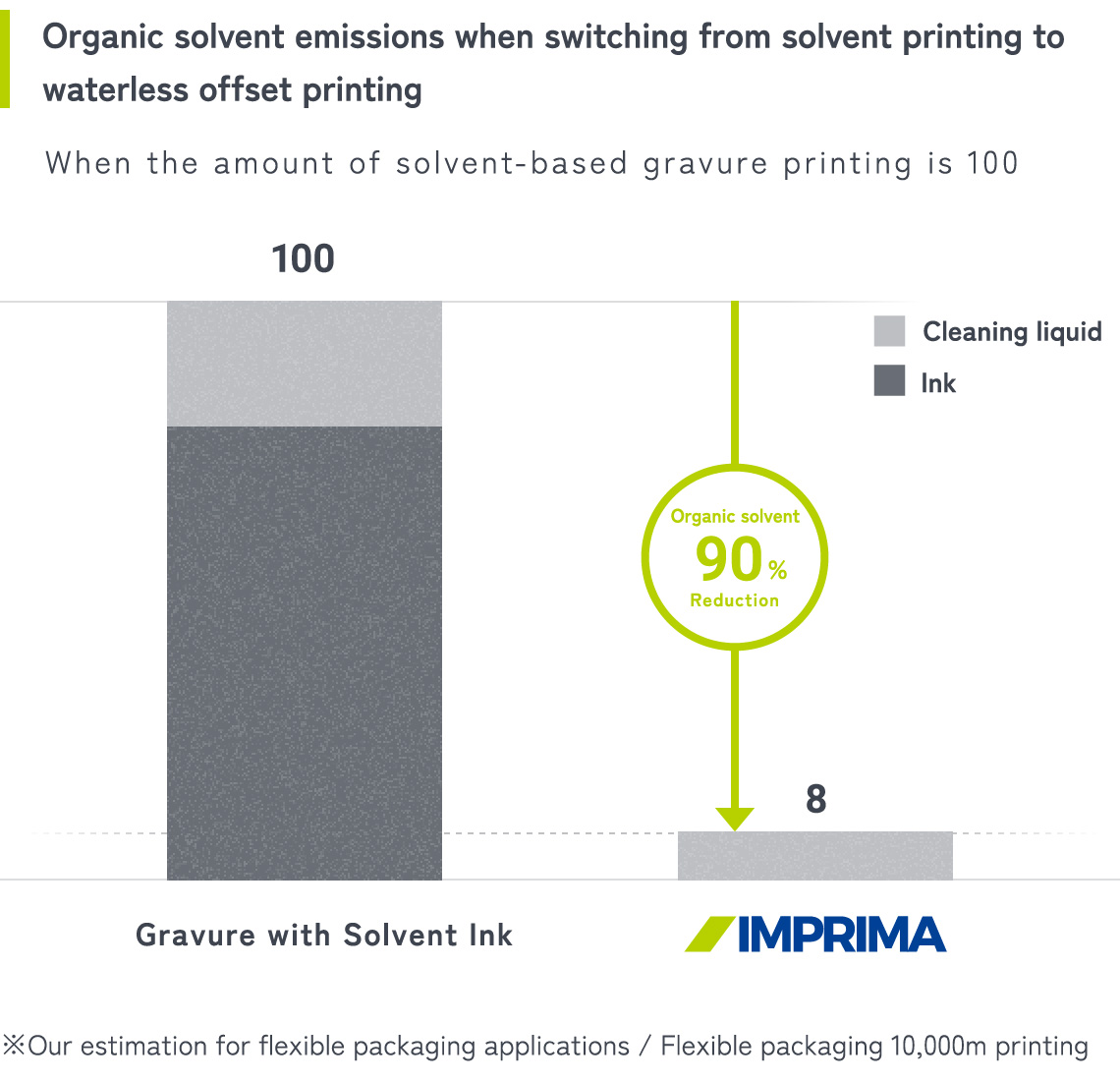

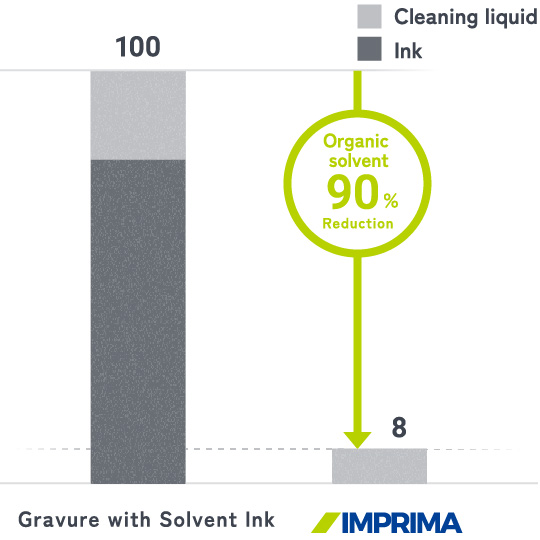

Organic solvent emissions when switching from solvent printing to waterless offset printing

When the amount of solvent-based gravure printing is 100

※ Our estimation for flexible packaging applications

Environmental superiority (2): Reduced VOC emissions

VOC stands for "Volatile Organic Compounds," which are emitted daily from manufacturing sites, cars, and households among other things. They are known for causes of air pollution in recent years due to the generation of photochemical oxidants and SPM in the atmosphere. Furthermore, the continuous exposure of VOCs is found to increase the risk of respiratory diseases and visceral disease as well as having headaches and dizziness.

The waterless offset printing system with IMPRIMA™, drastically reduces VOCs in comparison to solvent-based printing methods such as solvent gravure printing and solvent flexographic printing. This not only preserves the global environment from air pollutions, but also contributes to health of workers by keeping manufacturing sites clean.

Negative effects of VOCs on health

Long-term Exposure

- Irritation of the eyes, nose, and throat

- Nausea

- Fatigue

- Allergic skin reactions

- Damage to the liver, kidneys, and central nervous system

Short-term Exposure

- Irritation of the respiratory tract

- Headaches

- Dizziness

Organic solvent emissions by printing method

Organic solvent emissions when switching from solvent printing to waterless offset printing

When the amount of solvent-based gravure printing is 100

※ Our estimation for flexible packaging applications / Flexible packaging 10,000m printing

Standardize printing skills and achieve high quality

Printed images are reproduced through a combination of dense ink and the gradation of small halftone dots. Since printed materials such as packaging and labels play an important role as the face of a product or company, strict quality control is required. Hence, it is necessary to stabilize the density and the reproduction halftone dots. In addition, conventional water-based offset printing systems require workers engaging in the daily management of printing machines and materials to have the high level of skills, facing difficulties in securing and training human resources.

In comparison, the waterless offset printing system with IMPRIMA™ has fewer variables and results in the simplified operations to more easily control the quality. We can expect to increase the production efficiency with the standardized printing skills. Furthermore, we can achieve the higher quality by reproducing high-definition dots.

Image reproduction on printed material

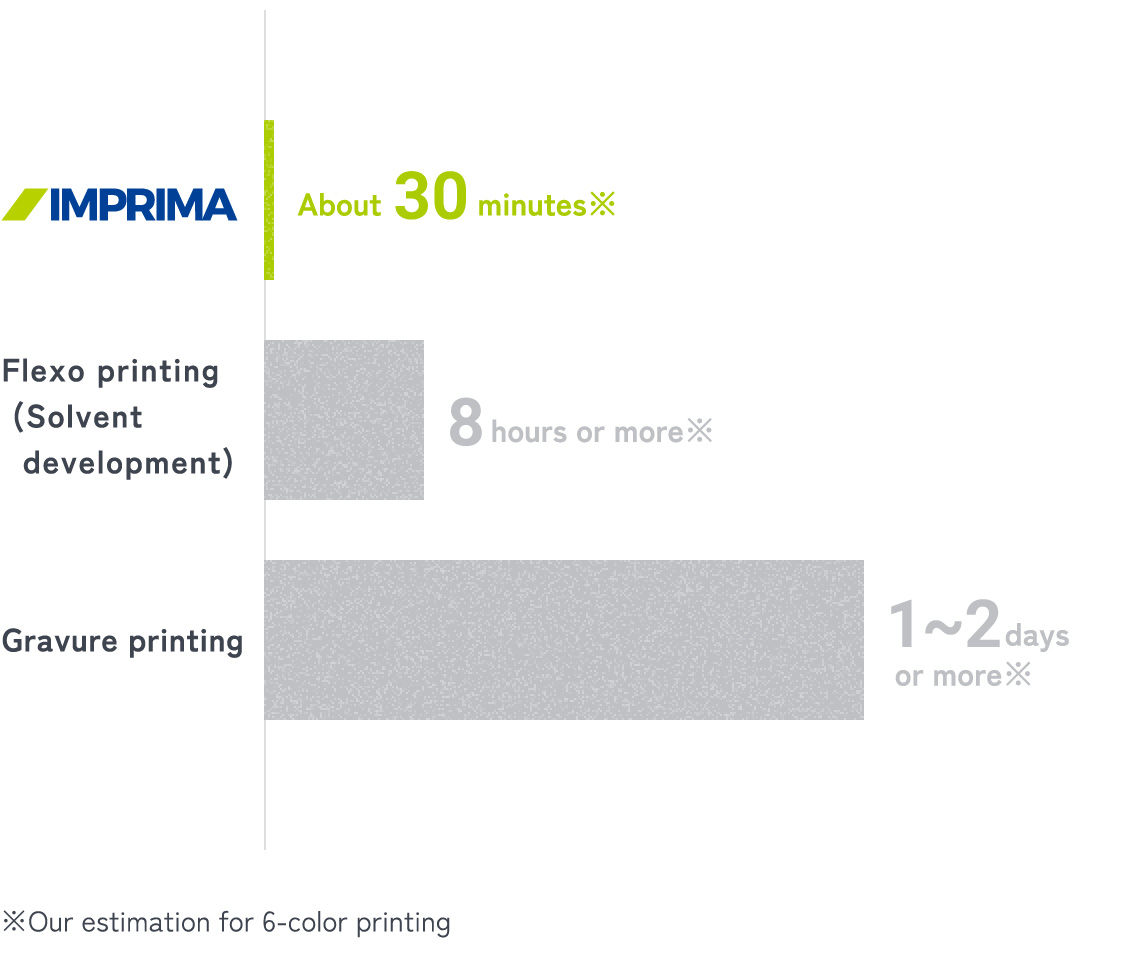

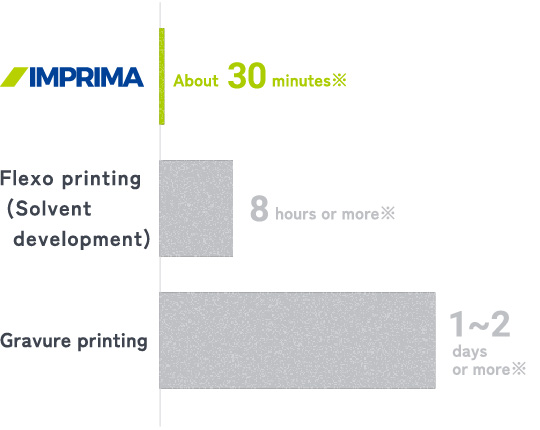

Economical production for multi-product and small-lot

In the contemporary world, our lifestyles and values have become more diverse, and consumers' product demands are also constantly changing. In addition, the product life cycle has been shortened year by year. This social background needs "multi-product, small-lot production" to flexibly respond to the instant demand. Compared to other printing methods, the waterless offset printing system with IMPRIMA™ can greatly reduce the amount of time required to produce plates necessary for printing product packaging and labels.

Even in terms of cost, since the system can handle small to medium lots, it is possible to produce a large variety of products even in small quantities, achieving economical production that fits the current trends.

Plate making time comparison

- ※

- Our estimation for 6-color printing

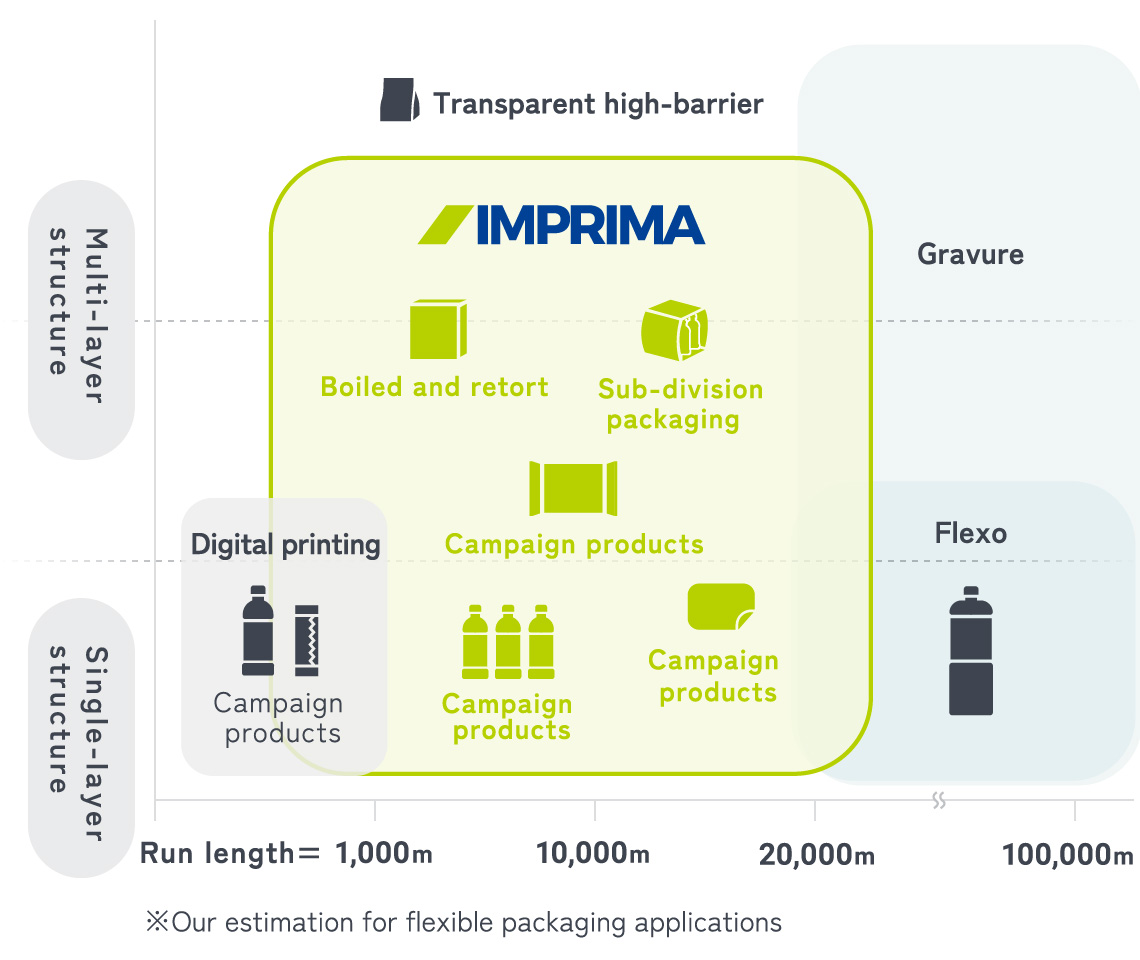

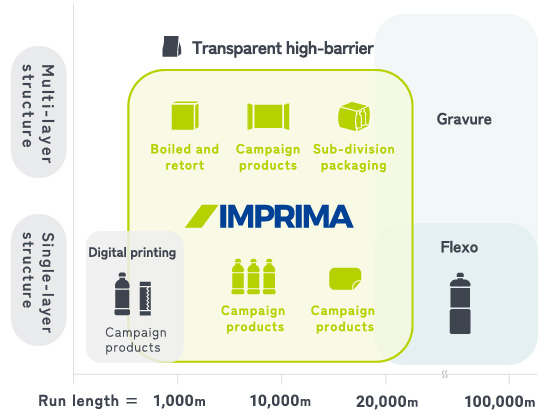

Optimal printing lot of IMPRIMA™ - Capturing market needs through the wide run lengths

- ※

- Our estimation for flexible packaging applications

Versatile applications

IMPRIMA™, which can maintain consistent quality, is used not only for paper materials but also for a wide variety of everyday and industrial products such as labels and security cards.

Labels

IMPRIMA™, which is capable of high-definition printing, provides consistent quality with less variation in halftone dots and color density on labels, where quality control is difficult. In addition, the high printing durability of the plate makes it possible to use in medium- to large-lot jobs, making it highly productive.

- High definition

- Quality stability

- Productivity

Metal containers

Metal containers for food and cosmetics are printed in the forms of tin steel, and aluminum sheets and assembled later on. IMPRIMA™ provides consistent quality in terms of density and halftone dot reproduction. With the fewer defective products, it contributes to the reduction of material waste and improvements in productivity.

- Quality stability

- Reduction of material waste

- Productivity

Newspapers

The Cortina, a dedicated waterless newspaper printing press, does not require ink changes and has high productivity for commercial printing. It reduces the amount of paper and other manufacturing waste with its shorter preparation time and faster start-up. It also offers excellent color and image reproduction, enabling high-definition printing.

- Productivity

- Reduction of manufacturing waste

- High definition

Paper containers

Paper containers printed with IMPRIMA™, which is free of dampening water, are characterized by easy density reproduction and high pattern-density stability. It also reduces CO2 emissions the amount of waste generated during manufacturing.

- Stable density

- Global warming countermeasures

- Reduction of manufacturing waste

Decorative molding film

Decorative molding film printed with IMPRIMA™ achieves a higher design quality than that with existing technologies. Even when printing new designs for automobiles, motorcycles, and home appliances, the consistent quality and the excellent productivity are guaranteed.

- Design quality

- Quality stability

- Productivity

Flexible packaging

IMPRIMA™ is used in printing flexible packaging thanks to its effectiveness in reducing CO2 and VOC emissions to combat global warming. In addition, the use of EB curing ink has made it possible to avoid the usage of starting materials, contributing to food safety.

- Global warming countermeasures

- VOC reduction

- Food safety

Building materials

For building materials such as sliding door paper, high-definition printing and consistent quality control can be achieved by combining other printing methods with IMPRIMA™ offset printing. It is easy to match colors so there is less waste paper, and it is also characterized by the reduction of waste during production.

- High definition

- Quality stability

- Reduction of manufacturing waste

Security / Currency / Bonds

IMPRIMA™ is used by many companies and local governments for security printing, where cutting-edge technology is used to prevent counterfeiting. In addition to high-definition printing and consistent quality, it also reduces waste during manufacturing, such as raw material loss.

- High resolution

- Quality stability

- Reduction of manufacturing waste

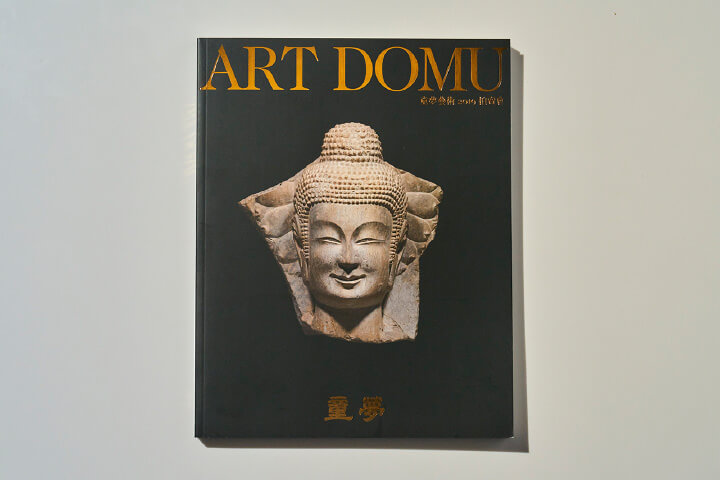

Books

IMPRIMA™ waterless printing provides consistent quality with minimal variation in halftone dots and density, allowing for high-definition book printing with less bleeding and closer reproduction of image data.

- Quality stability

- High definition

- Global warming countermeasures